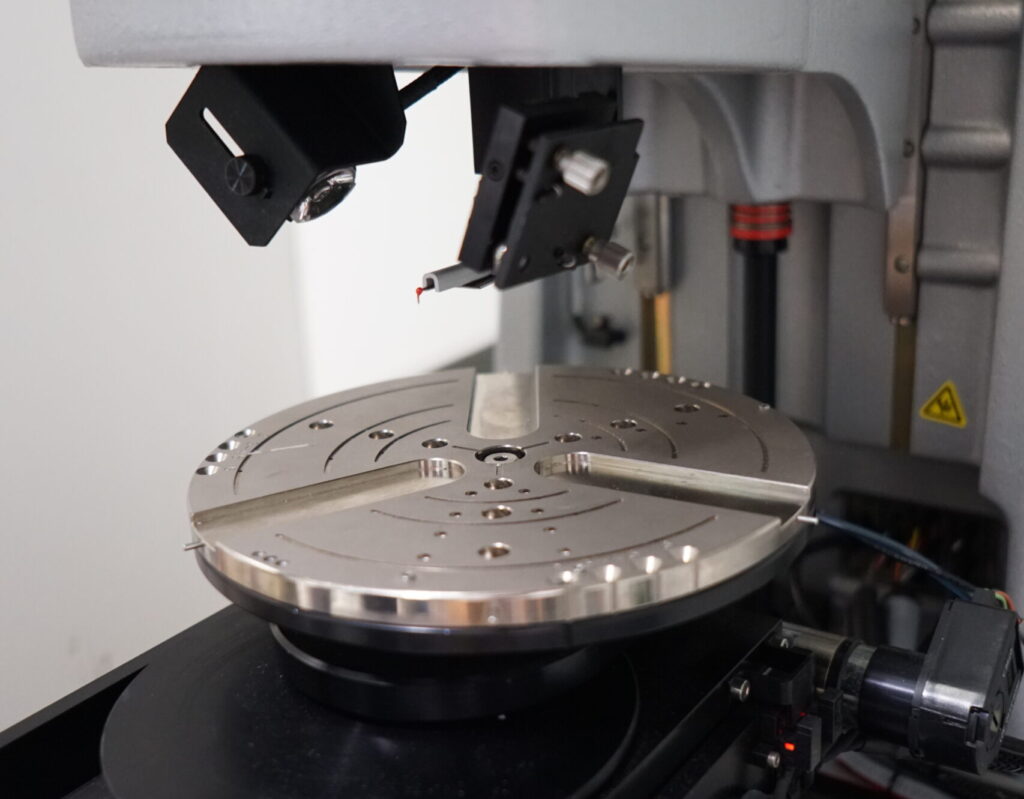

Dektak 150 / Veeco

The method reveals surface roughness and waviness, texture, and even wear patterns. The latter might be crucial for industries that rely on material integrity, such as aerospace and electronics. Accurate surface topography mapping ensures components meet stringent quality standards on large sample areas.

The diamond stylus records fine height differences in a surface topography. The lateral size and vertical range that can be scanned by stylus profilometry is much larger compared to AFM.

A customer develops micro- and nanostructures on substrates for applications like flexible electronics or microfluidics. Profilometry reveals the surface topographies, ensuring the integrity and functionality of these structures on solid or flexible substrates.