Tribometry

Tribometry

Device

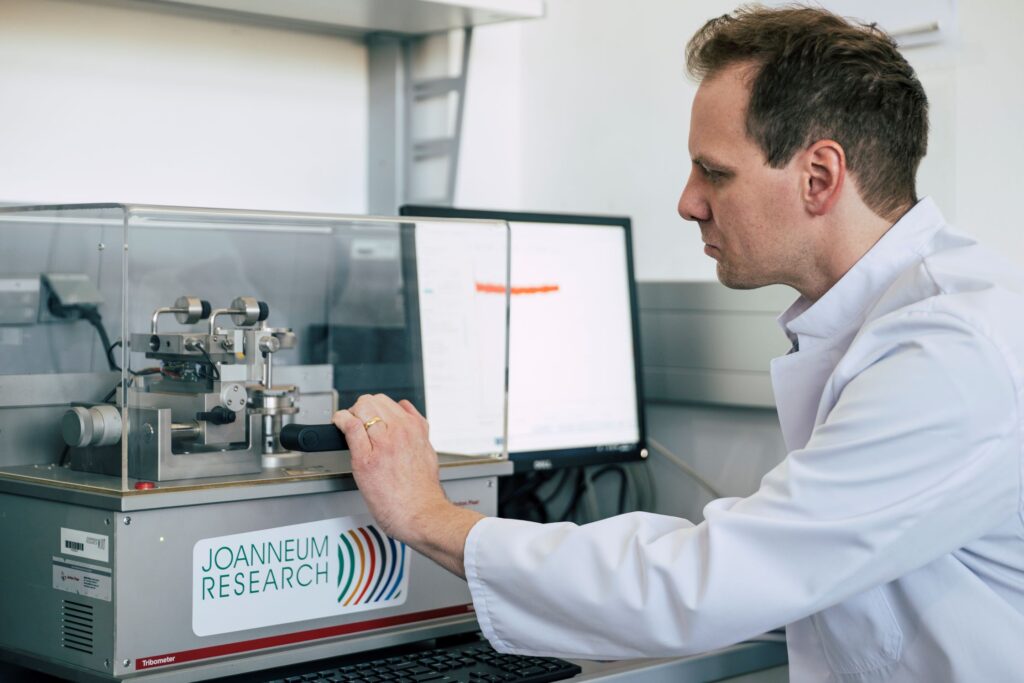

TRB3 Pin-on-Disc Tribometer / Anton Paar - CSM

Expected Result

Quantitative data on the wear rate and friction coefficient of materials, allowing manufacturers to evaluate durability and performance under sliding conditions.

Method

Tribology testing using a pin-on-disc setup to measure friction and wear properties under controlled environmental conditions. The TRB3 is designed to study the wear resistance of coatings and materials by applying a constant load and monitoring the wear over time.

Case Study

An automotive parts manufacturer tests a hard coating for brake discs. Using the TRB3 tribometer, the wear rate and friction properties are assessed under conditions simulating real-world use, providing valuable insights into the coating’s durability and effectiveness in reducing wear.

TRB3 Pin-on-Disc Tribometer / Anton Paar

Specifications

- Sample size /thickness 1 – 50 / 0.1 – 50 mm, bulk and thin films, metals, alloys, polymers

- Standards: ASTM G99, G133, DIN 50324

- Environmental Monitoring: Real-time temperature and humidity sensors

- Ball Options: 6 mm Al₂O₃, 100Cr6, WS 1.4301, PA12, POM,…

- Speed and Load: Customizable for various testing protocols