X-Ray Photoelectron Spectroscopy (XPS)

X-Ray Photoelectron Spectroscopy (XPS)

Device

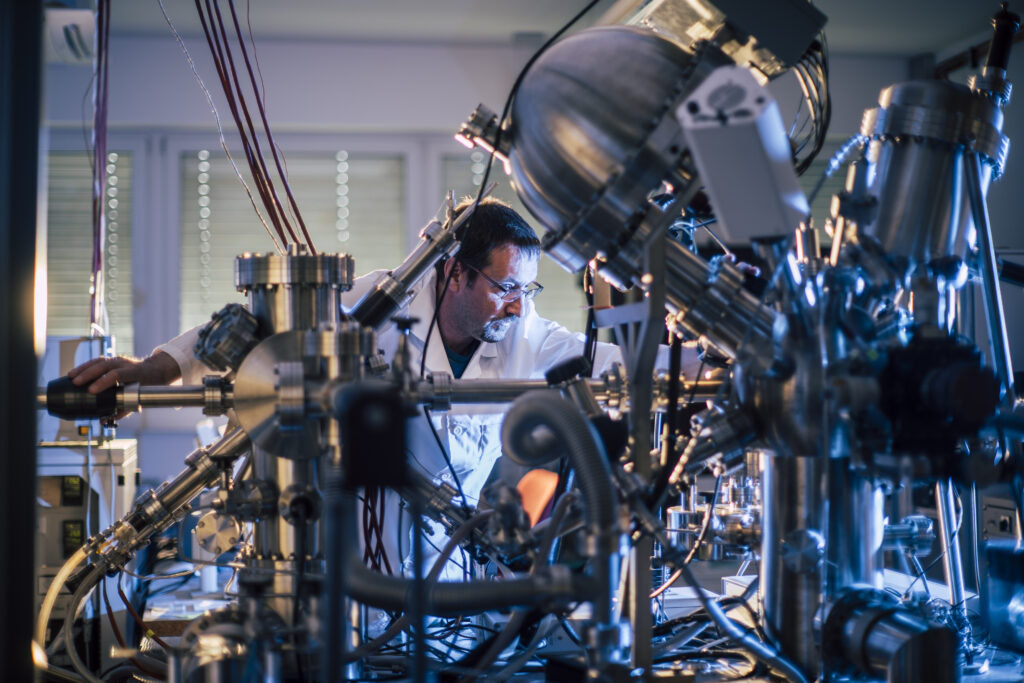

X-Ray Photoelectron Spectroscopy (XPS) / Omicron Nanotechnology

Expected Result

The analysis yields comprehensive data on the chemical composition and binding of the surface, offering insights into material purity, state after surface treatments, and potential contamination issues. This information is crucial for optimizing surface properties in various applications.

Method

X-rays striking a sample of interest induce the emission of photoelectrons from surface near areas (about 5nm information depth). The kinetic energy and the number of these electrons give an idea on the chemical composition of the surface and quantifies their amount. Further information binding states is also accessible.

Case Study

A customer wants to investigate the surface modifications of treated polymer foils, providing insights of the developed advanced coatings and the performed surface treatments. The analysis of the surface chemistry helps the customer to tailor the properties of the performed surface modifications. Sputtering allow to identify interpenetration of different components.

X-Ray Photoelectron Spectroscopy (XPS) / Omicron Nanotechnology

Specifications

-

Analyzed surface-area: around 1 mm in diameter

-

Maximum sample size: 10 x 10 mm2

-

Multiprobe UHV-surface-analysis system (Omicron Nanotechnology)

-

X-ray source: DAR400 aluminium-anode, 1486,70eV (Al Kα1-line)

-

XPS detector: hemispherical analyzer, type EA 125

-

Argon sputtering enables sample cleaning as well as depth dependent composition analysis